Sapele Hardwood: Under the Microscope

Annabel Fenwick | 7th November 2016

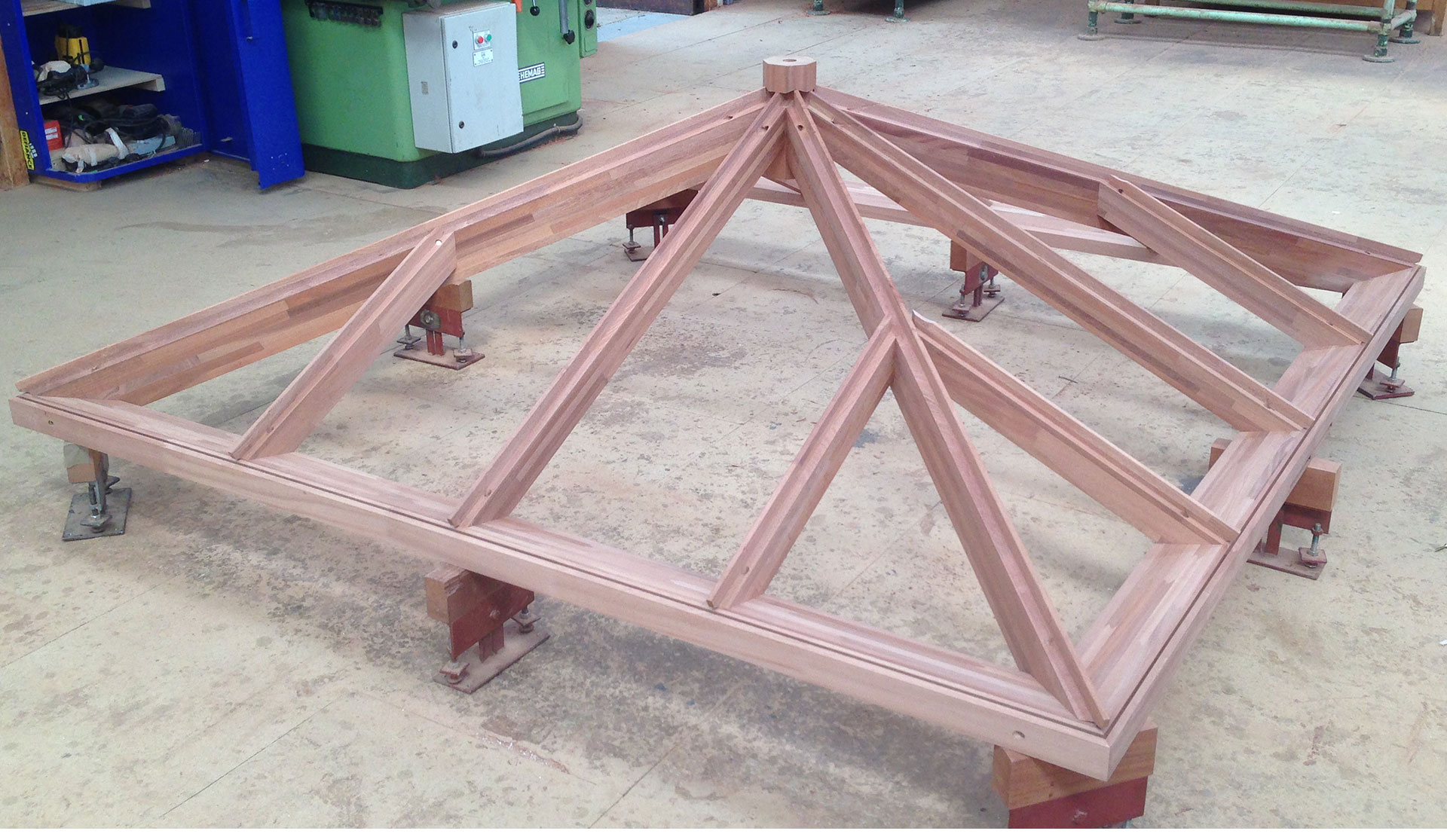

In this blog we look at the principal building material used to frame our 'Classic' range of roof lanterns - FSC® certified Sapele.

Sapele is an excellent grade quality hardwood; while reminiscent of mahogany (indeed it’s part of the same family) it’s much harder than both its African or American counterparts and with respect to resistance to indentation, bending strength, stiffness, and resistance to shock loads, is practically equal with English oak. Indeed it’s classified as a class one hardwood having a density of 640 kg per cubic metre. The FSC® certification ensures buyers of a legal and environmentally sustainable supply chain and also ensures compliance with government procurement regulations.

This high density is the crucial feature of sapele; it doesn’t take in moisture in the same way as lesser softwoods and has low resin levels. Over time therefore sapele is considerably less prone to seasonal changes in the environment. This makes it an ideal choice with respect to roof lanterns which can be particularly vulnerable to extreme temperatures in the summer months due to heat build-up through the glass. Softwood in comparison has a low density and its high resin levels mean that in periods of high temperatures, resin leakage can occur. This clearly has a grave impact on the paint finish and the timber’s subsequent longevity.

The high density of sapele timber also means that it bruises far less easily - a hugely important consideration when working with timber. It’s density also offers a manufacturer the opportunity to create sharper details and crisper mouldings which is vital when looking to produce a roof lantern with a high level of refinement.

Further sapele hardwoods natural strength also offers the opportunity to create contemporary style roof lanterns within a timber oeuvre. Thick, clunky rafters and crude detailing are clearly not synonymous with a modern looking aesthetic so using a hardwood is vital in the creation of a lantern with thin rafters and precise detailing. It also offers the manufacturer more scope to change the arrangement of the roof configuration and rafter sizes which many architects find appealing as there’s greater flexibility with regard to overall design.

The density of sapele also means the timber has better acoustics; it absorbs sound a good deal more than a softwood and certainly more than aluminium. When many roof lanterns are incorporated as part of an open plan kitchen and family room, this fact is not an inconsequential point to consider.

In addition to these all these benefits, here at Just Roof Lanterns we use sapele in an engineered form. Fundamentally, using engineered timber makes the hardwood even stronger, even more durable. The lamination process (usually three layers of wood glued together) means the timber is even less prone to general movement (warping, bending, twisting etc.). In essence, it significantly enhances the lifespan of the timber.

Engineered wood is also more environmentally friendly than using standard solid wood; it preserves and extends the use of the forest resource by using a higher percentage of fibre, which previously was burned or left to rot. Further, the use of wood from residual sources, plantations and second-growth forests reduces the pressure to harvest more forest area.

So to conclude, sapele is the optimum choice in the manufacture of a timber framed roof lantern. It offers the highest level of strength and durability and the lamination process further maximises its stability. In combination with the latest technical innovations including our own patented aluminium capping system on the exterior, we believe our roof lanterns at Just Roof Lanterns are truly built to last in terms of both specification and refinement.